Key Features

- BaleTrak™ Pro monitor-controller

- Adjustable hitch to match wide array of tractor drawbar heights

- MegaTooth™ pickup offers extra toughness in a regular pickup width

- Exclusive DiamondTough™ belts with plate-type splices

Features

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controller

The 459, 459E, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 569, and 569 Silage Special Round Balers feature the BaleTrak Pro monitor-controller.

The 449 Round Baler offers the option to have the BaleTrak Pro monitor-controller. On the 449 and 459E this monitor does not allow for all the features of the BaleTrak Pro monitor such as bale shape bars and net wrap. Wrap settings and bale size can be viewed from the monitor.

This feature allows the operator to both monitor and control important baler functions for productivity and convenience right from the tractor seat.

A 24-bar graph makes it even easier to make a uniform-shaped bale that will stand tall and remain firm over time. The 24 bars provide smaller increments of change to give the operator a more precise indication of bale shape. The 449 and 459E Round Balers do not utilize the bale shape bars like the other models do.

Preset factory settings allow the operator to turn on just one switch and go bale; it's just that easy.

BaleTrak Pro provides the following monitoring functions:

- On/off key - turns monitor on or off

- Twine/net key - selects between twine or net wrap

- Baler symbol - gate closed, ready to bale

- 24-bar graph - bale-shape indicators

- Small bale symbol - near-full bale

- Bale with twine/net wrap symbol - stop forward travel, wrapping started, maintain power take-off (PTO) speed

- Baler with bale ejecting symbol - open gate and eject bale

- Numerical display - shows bale diameter increasing in inches

- Variable core symbol - on, if selected (variable core kit optional)

- Battery symbol - low-voltage indication

- Stop sign symbol alarm - stop baling immediately, investigate/correct

- Bale with net wrap symbol - net wrap did not feed or knife did not cut material

- Baler with gate open symbol - gate open, ejecting bale

- Numerical display - bale counter, daily/lifetime totals

- Error code display - displays the error code number for diagnosing the electrical system

- Slip clutch alert kit (optional)

BaleTrak Pro provides the following controlling functions:

- Set bale size

- Set twine spacing/net wrap

- Set the number of twine end wraps

- Manually extend twine arms

- Manually retract twine arms

- Adjust starting time of net wrap application

- Set the number of net wraps

- Set the distance of twine from bale ends

- Manual twine actuator movement with electronic bypass

- Onboard diagnostics

Features of BaleTrak Pro monitor-controller:

- Simple to operate; just turn on and bale

- Factory settings are preprogrammed but can be changed by the operator, if desired

- Added flexibility; the operator can adjust the baler for different crop conditions

- Increases productivity; the operator stays on the tractor

- Single self-contained processor box mounts on the tractor

Override switch

Override switchBaleTrak Pro has a manual twine arm override switch (1), which is included with the monitor's wiring:

- Allows operator to manually wrap twine on bale if BaleTrak Pro monitor-controller malfunctions

- Connects to tractor three-terminal convenience outlet

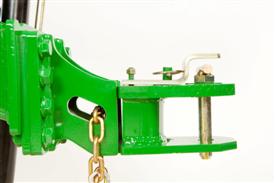

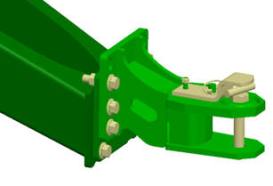

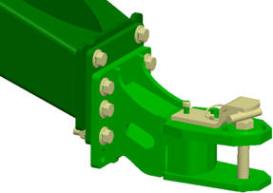

Side view of adjustable hitch

Side view of adjustable hitch Front view of adjustable hitch

Front view of adjustable hitchThe 9 Series Round Balers come standard with an adjustable hitch. This feature allows the hitch height to be adjusted to optimize crop-feeding performance. Due to the wide array of tractor tire sizes and drawbar heights, hitch adjustment may be necessary to get the proper feed opening of the baler. The adjustable hitch eliminates the need for the 51-mm (2-in.) thick tractor drawbar kit (AE57344) because it has a wider opening.

Benefits of the adjustable hitch:

- Ability to match baler to numerous tire sizes

- Allows for drawbar height to fall within 330 mm to 559 mm (13 in. to 22 in.) from top of drawbar to the ground

- Eliminates narrow feed opening on baler which can cause plugging

- Allows pickup head to follow terrain without missing crop

All eight bolts must be used when adjusting the hitch. There are four different positions as shown below:

Position 1 (top) - Regular and MegaTooth™ pickups

Position 1 (top) - Regular and MegaTooth™ pickups Position 2

Position 2 Position 3 (factory setting) - MegaWide™ Plus pickups

Position 3 (factory setting) - MegaWide™ Plus pickups Position 4 (bottom)

Position 4 (bottom)Also standard on all 9 Series Round Balers except the 459E is the drawbar flap. This helps to eliminate hay from getting caught on the hitch of the baler. The drawbar flap is designed to allow the operator to remove or attach the flap without having to unhook the baler from the tractor.

Drawbar flap

Drawbar flap Drawbar flap installed on baler

Drawbar flap installed on baler Regular pickup on 459E Baler with converging wheels

Regular pickup on 459E Baler with converging wheels

Mounted in front of the baler wheels and directly below the bale chamber, the pickup hugs the ground for clean crop retrieval. Hay movement is minimized.

- V-belt driven

- 449, 459E, and 459 Baler pickups are 116.6 cm (45.9 in.) wide

- 559 and 569 Baler pickups are 156 cm (61.4 in.) wide

- Large reel shaft and reel bearing

The small-diameter, low-profile pickup allows for good ground gauging and clean crop retrieval.

- Handles large, heavy windrows of hay and high-moisture crops

- Feeds hay directly to the forming chamber to reduce crop loss

- Low-profile pickup minimizes hay lift to reduce chaffing to retain hay quality

Side flares prevent hay from blowing off the pickup ends and reduce hay loss.

The closely spaced pickup teeth extend to the baler side sheets to help build straight-edged bales.

Standard on regular and MegaTooth™ pickups, compressor rods are contoured to control hay over the pickup radius for positive feeding. The compressor rack can be adjusted upward or downward to match the volume of material in windrow and can be easily removed to match crop conditions.

Adjustable crank handle

Adjustable crank handle

The adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular, MegaTooth and MegaWide™ Plus pickups

- Hydraulic pickup lift comes standard on premium machines

MegaTooth pickup

MegaTooth pickup MegaTooth pickup

MegaTooth pickupAvailable on the 569 Baler only, John Deere exclusive, patented MegaTooth pickup is the same width as the bale chamber, but includes these heavy-duty components as standard equipment:

MegaTough pickup teeth

MegaTough pickup teeth

- Mega teeth, located at the ends of the pickup, pull crop around the flares

- MegaTough™ pickup teeth provide greater strength and durability

- Exclusive square design handles high-impact loads without yielding

Cutout clutch protected feeder drive chain

Cutout clutch protected feeder drive chain

The balers are chain-driven for positive bale starts with cutout clutch protection. The pickup is now being driven off the right-hand side of the baler and bypasses the starter roll chain. This will allow for reduced wear on the starter roll chain.

Other features of the pickup include:

- Chain drive for positive bale starts

- Cutout clutch protected

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheels are standard on the MegaTooth pickup and provide smooth ground gauging over uneven terrain:

- Stiff rubber sidewalls

- No air pressure to maintain, which means no flat tires

- Adjustable to meet pickup tooth-to-stubble height requirements

Adjustable crank handle

Adjustable crank handle

The adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular, MegaTooth and MegaWide™ Plus pickups

- Hydraulic pickup lift comes standard on premium machines

MegaWide Plus pickup

MegaWide Plus pickup

A MegaWide Plus pickup is available on 449, 459, 559, and 569 Round Balers. It is base equipment on the 459 Silage Special, 559 Silage Special, 469, 469 Silage Special, and 569 Silage Special Balers.

This pickup makes baling easier, especially in wide or windblown windrows, and increases productivity; more hay volume means more bales per hour.

- Flare-to-flare width of 1.8 m (5.9 ft) on balers with a 1.2 m (4-ft) wide bale chamber

- Flare-to-flare width of 2.2 m (7.2 ft) on balers with a 1.5-m (5-ft) wide bale chamber

- MegaWide Plus pickup makes it easier to produce better-shaped bales and improves crop pickup in wide, windblown, or scattered windrows

- Mega teeth, located at the ends of the pickup, pull crop around the flares when baling wide or windblown windrows

- MegaTough pickup teeth provide greater strength and durability

- Exclusive square design handles high-impact loads without yielding

- Sturdy toothbar design

- Self-adjusting roller baffle

- Spiral rotor-feed system improves feeding in all crop conditions

- Chain driven for positive feeding

- Cutout clutch protected

- Semi-pneumatic gauge wheels

MegaTough pickup teeth

MegaTough pickup teeth

Mega and MegaTough pickup teeth are base equipment:

- Mega teeth, at the ends of the pickup, are heavy-duty for long life and improved crop retrieval

- MegaTough pickup teeth are designed to withstand the harshest baling conditions and provide long service life

Toothbars on 1.5-m (5-ft) baler

Toothbars on 1.5-m (5-ft) baler

The 1.2-m (4-ft) balers use a full-length, reinforced toothbar design.

The 1.5-m (5-ft) balers use a heavy, C-channel construction. The pickup toothbars are divided into two half-sections that mount to a center spider for increased strength and even crop feeding.

Roller baffle

Roller baffle

Available only on the MegaWide Plus pickup, the patented roller baffle is self-adjusting and produces smoother crop flow across the pickup. The roller also improves crop pickup in small windrows and prevents roll ahead of crop.

When combined with the MegaWide Plus pickup, this feeding system allows increased ground speed with less chance of plugging, for increased productivity in all field conditions.

- Self-adjusting

- Smoothes crop for even flow across pickup

- Allows for faster ground speed with less chance of plugging

- Increases operator productivity

Spiral rotor

Spiral rotor Auger and rotor feed system

Auger and rotor feed systemThe MegaWide Plus pickup uses a rotor feeding assembly, which mounts behind the pickup for smooth and even crop flow into the bale chamber.

- Augers and rotor teeth are driven on the same shaft, eliminating the need for additional drives.

- The rotor is fixed to the baler frame, allowing positive and even feeding into the bale chamber.

- Large-diameter converging augers have high crop-flow capacity, and auger scrolls help to force crop into the chamber.

- Spiral design enhances feeding in uneven windrows and reduces loading on the rotor.

Rotor stripper

Rotor stripper

Rotor strippers allow crop to be lifted from the rotor teeth into the chamber without cutting or wrapping the crop.

Cutout clutch protection and feeder-drive chain

Cutout clutch protection and feeder-drive chain

The MegaWide Plus pickups are chain-driven for positive bale starts with cutout clutch protection. The pickup is now being driven off the drive roll and bypasses the starter roll. This will allow for reduced wear and breakage of the starter roll chain.

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheels provide smooth ground gauging over uneven terrain and protection to the pickup.

- Stiffer rubber sidewalls

- No air pressure to maintain, which mean no flat tires

- Adjustable to meet pickup tooth-to-stubble height requirements

The pickup float springs are positioned for excellent flotation.

- Adjustable to meet varying field conditions

- Float springs only support the pickup reel

- Rotor assembly is fixed to the baler frame, eliminating additional weight on the pickup system

Adjustable crank handle

Adjustable crank handle

The adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

- Makes raising for transport or clearing obstructions easy

- Crank handle serves as a down stop

- Adapts to regular, MegaTooth and MegaWide™ Plus pickups

- Hydraulic pickup lift comes standard on premium machines

Bale-starting diagram

Bale-starting diagram

As the hay enters the forming chamber from the pickup, belts turn the hay immediately to form a tight, dense core.

Incoming hay then feeds between the bale and the lower-gate roll. Hay is tightly compressed into smooth, dense layers as it enters the bale.

Chaffing is greatly reduced to prevent loss and retain hay quality in the bale.

Full-sized bale in bale chamber

Full-sized bale in bale chamber

The idler arm rises with bale growth, forcing oil from the hydraulic cylinder through a pressure-relief valve:

- Maintains uniform bale density throughout the bale-forming process

Staggered belts

Staggered belts

John Deere's 178 mm (7-in.) wide diamond-tread design ensures fast bale starts and grips the bale to prevent slippage and reduce chaffing. The treads are self-cleaning to reduce carryover.

The belts are staggered to reduce the loss of fine material and are closely spaced to contain the hay for fast, easy starts.

The belts enclose 91 percent of the bale width to reduce loss of fine material and retain hay quality.

The staggered belt roll design enables any loose hay under or behind the belts to be returned to the pickup and into the baler.

This design helps to prevent buildup at the front of the baler, which could cause hay loss and belt or splice damage.

DiamondTough triple-weave belts

DiamondTough triple-weave belts

The 459, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 469 Premium, 569, 569 Silage Special, and 569 Premium use DiamondTough belts.

Belts are constructed using a patented triple-weave process of nylon and polyester materials.

They have the strength to handle heavy shock loads and help maintain consistent belt length.

The DiamondTough belts are more puncture and tear resistant than other belts on the market and provide improved belt life and reliability.

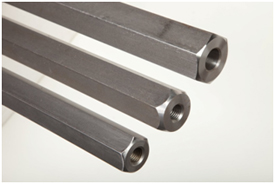

Plate-type fasteners

Plate-type splices

Plate-type splices

The 459, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 469 Premium, 569, 569 Silage Special, and 569 Premium use plate-type fasteners.

This closed-loop design uses a plate fastener with pre-assembled rivets that lock the fasteners into the belt, providing a powerful vice-type grip on the belt.

- The plates and rivets are manufactured from high-tensile stainless steel.

- Strong belt splices mean less maintenance and more productivity.

- The loop area is cold forged, making it extremely wear resistant in the coupling area, resulting in a very long cycle life.

- The spring steel pin is notched and locks into the splice connection without having to bend the pin or use external retainers.

High-flotation tires

High-flotation tires Baler with XL high-flotation tires

Baler with XL high-flotation tires The XL high-flotation 21.5L-16.1 10 PR tires (1) are available on 459, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 469 Premium, 569, 569 Silage Special, and 569 Premium. All machines must have MegaWide™ Plus pickup.

The high-flotation 14L–16.1 tires (2) are available on all models except the 459E, 469 Premium, 569 Silage Special, and 569 Premium. The 14L – 16.1 tires have replaced the 31 x 13.5 tires.

The larger tires absorb shock loads and improve the ride in rough or pivot track ground, decreases compaction in soft ground, and allows increased ground speed for increased productivity.

Larger shafts – 8 Series, 9 Series, 9 Series Premium

Larger shafts – 8 Series, 9 Series, 9 Series Premium

The 9 Series Round Balers have increased their durability by increasing the shafts and bearings on the top and bottom rolls of the baler. The size of the shafts and bearings are listed below:

- 8 Series - 31.8-mm (1.25-in.) shaft and 90-mm (3.5-in.) outside diameter (OD) bearing (this bearing requires a quill assembly to fit in the roll)

- 9 Series - 38.1-mm (1.5-in.) shaft and 130-mm (5.1-in.) OD bearing (this bearing does not require a quill assembly to fit in the roll)

- 9 Series Premium - 44.5-mm (1.75-in.) shaft and 130-mm (5.1-in.) OD bearing

The #9 and #11 rolls receive the most wear and stress since they have the most surface area contact with the belts. The lower gate roll also carries the weight of the bale. By increasing the shaft size, strength is added to the baler. The larger bearings will run cooler, therefore, increasing the life of the bearings.

Diagram of rolls on baler

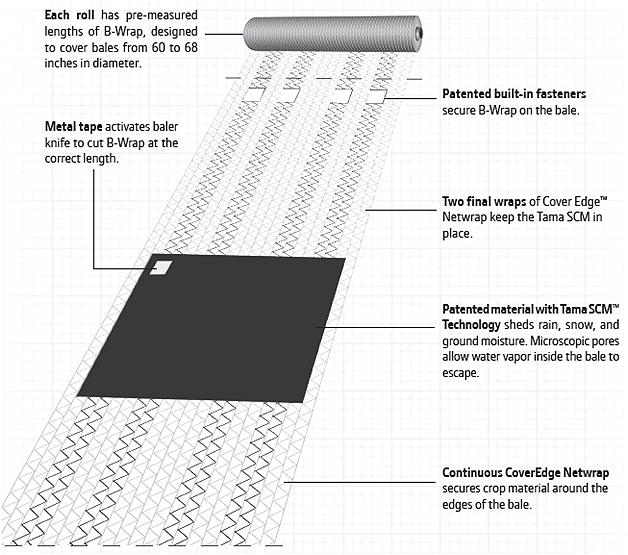

Diagram of rolls on baler B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap is applied onto bales just like net wrap, but it protects hay much better than net. B-Wrap includes a special patented material with Tama SCM™ technology. It sheds rain and snow while protecting the bale from ground moisture. Plus this material has microscopic pores that let water vapor inside the bale escape. B-Wrap is the alternative to indoor storage, delivering barn-quality hay without the barn.

B-Wrap protects bale quality in all types of crops. Use B-Wrap on top-quality hay, as well as straw, peanut hay, and corn stalks.

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is easy to install. The kit includes wiring that connects a sensor to the bale monitor and an EPOM chip is also added to the bale monitor.

The B-Wrap kit is available for all 9 Series Round Balers and comes as standard equipment on the 469 Premium and 569 Premium.

This kit also works on these 7 and 8 Series Round Balers equipped for netwrap: 457, 457 Silage Special, 467, 467 Silage Special, 557, 567, 458, 458 Silage Special, 468, 468 Silage Special, 558, and 568 Round Balers. (7 and 8 Series Balers must be equipped with a speed compensation/slip-clutch alert kit (BE32317). This speed compensation kit was standard equipment on some later 8 Series Balers. Balers with this kit have sensors on the slip clutch.)

A roll of John Deere B-Wrap

A roll of John Deere B-Wrap

A roll of B-Wrap looks and weighs similar to a roll of net, and B-Wrap loads into John Deere round balers exactly like net.

B-Wrap is designed for bales 152.4-cm to 172.7-cm (60- to 68-in.) in diameter. A roll of B-Wrap for 1.5-m (5-ft) balers has 35 premeasured portions, enough to wrap exactly 35 bales. A roll of B-Wrap for 1.2-m (4-ft) balers will wrap exactly 45 bales.

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

B-Wrap works in round balers much like netwrap. The B-Wrap kit allows a baler to use either B-Wrap or net. Switching between net and B-Wrap will take less than 5 minutes. Simply switch rolls, properly thread the new wrap into the baler, and then change bale monitor settings.

Here is how B-Wrap works in the baler. When a bale reaches the maximum size programmed into the monitor, the operator stops forward travel and wrapping begins. The first length of B-Wrap is John Deere CoverEdge™ netwrap. John Deere CoverEdge goes right over the edge or the bale, pulling in loose crop material, giving the bale a solid, weather-resistant shape.

The next length of B-Wrap includes the patented material with Tama SCM technology. It sheds rain and snow, and protects bales from ground moisture. The final length covering a bale is two more wraps of John Deere CoverEdge net. This securely holds the weather-resistant Tama SCM in place.

Roll of B-Wrap showing the net wrap and patented material

Roll of B-Wrap showing the net wrap and patented material

Metal tape on the SCM activates the knife, cutting the B-Wrap at exactly the predetermined length. The operator then backs the baler up about 3 m (10 ft) and ejects the bale. Built-in fasteners keep B-Wrap in place during storage.

Built-in fasteners secure B-Wrap to the bale

Built-in fasteners secure B-Wrap to the bale

Limitations of B-Wrap:

- While B-Wrap does allow moisture inside the bale to escape, baling hay too wet will cause mold to form. B-Wrap is for dry hay only. Operators should bale hay at the same moisture level they would when using net.

- B-Wrap can dramatically reduce bale damage caused by ground moisture, but bales must be stored in a well-drained location.

- To make sure the seam of the Tama SCM is in the proper location, bale kickers and bale ramps must be deactivated. The bale operator must back up about 10 ft before ejecting a B-Wrap bale.

- B-Wrap does cost more per bale than net wrap, but it protects feed value much better. Users report that hay and straw looked and smelled like the day it was baled, even after a winter stored outside.

- B-Wrap is only available initially with a standard kit. The standard kit (BE32467) requires the operator to shut off the PTO with each bale.

- Full production available in US and Canada for 2014.

Bale

| Size | Diameter 81 to 183 cm 32 to 72 in. Width 157 cm 62 in. |

| Weight | Full-size bale in dry crop 998 kg 2,200 lb Max. allowable for silage bale 1,089 kg 2,400 lb |

Baler

| Base weight | 2,145 kg 4,730 lb |

| Weight* | With 31.5x15 tires: 3,003 kg 6,620 lb |

| Length | Gate closed 371 cm 146 in. Gate open 475 cm 187 in. |

| Height | Gate closed 279 cm 110 in. Gate open 368 cm 145 in. |

| Width | With standard tires 286 cm 113 in. With opt. tires (Hi-Flotation) 333 cm 131 in. |

Bale forming

| Forming chamber | Variable |

| Belts-other | Number Eight belts Strength Triple weave Width 17.8 cm 7 in. Length, regular Four: 1,334 cm 525 in. Length, staggered Four: 1,348 cm 531 in. Fabric Diamond tough triple weave Texture Diamond tread |

| Enclosed % of bale surface | 91 percent |

| Belt splices | Plate-type splices |

| Density control | Adjustable hydraulic, isolated from tractor |

| Bale size indication | Electronic display on monitor |

Regular pickup

| Width | Inside 156 cm 62 in. Flare 180 cm 71 in. |

| Drive | Roller chain with V-belt |

| Bars | Four |

| Number of teeth | 96 |

| Tooth spacing | 6.6 cm 2.6 in. |

| Lift control | Crank standard Hydraulic optional |

| Gauge wheels | Semi-pneumatic standard |

| Stripper diameter | 25.4 cm 10 in. |

Mega wide pickup

| Width | Inside 196 cm 77 in. Flare 221 cm 87 in. |

| Drive | Roller chain with slip clutch |

| Bars | Four |

| Number of regular teeth | 120 |

| Number of mega teeth | Eight |

| Tooth spacing | 6.6 cm 2.6 in. |

| Lift control | Crank standard Hydraulic optional |

| Gauge wheels | Semi-pneumatic standard |

| Stripper diameter | 25.4 cm 10 in. |

Mega tooth pickup

| Width | Inside 155 cm 61 in. Flare 180 cm 71 in. |

| Drive | Roller chain with slip clutch |

| Bars | Four |

| Number of middle teeth | 80 |

| Number of mega teeth | 16 |

| Tooth spacing | 6.6 cm 2.6 in. |

| Lift control | Crank standard Hydraulic optional |

| Gauge wheels | Standard |

| Stripper diameter | 25.4 cm 10 in. |

Wrapping system

| Control | Automatic |

| Type | Standard Electric |

| Twine arms | Two |

| Twine ball capacity | Eight |

Monitor

| Monitor console for tractor | BaleTrak Pro |

| Gate closed | Symbol on monitor |

| Bale forming | Bar graphs |

| Bale size | Mechanical and digital |

| Near full bale | Audible alarm and symbol |

| Full bale | |

| Twine arm position Indicator | Mechanical |

| Auto wrap | Yes |

| Oversize bale | Audible alarm and symbol |

Surface wrap

| Available | Cover edge optional |

Tire size

| Standard | 14L-16.1, 8-ply |

| Optional | 21.5Lx16.1, 10-ply |

Driveline

| Drive protection | Slip clutch |

| PTO speed | 540 or 1,000 rpm |

| Type | Constant velocity, category 4: 540 rpm Constant velocity, category 5: 1,000 rpm |

| PTO lockback collar on tractor hookup | Yes |

| PTO 60-degree free rotation |

Tractor Requirements

| Minimum PTO | 56 kW 75 hp |

| Hydraulic SCV valves | One |

Silage baler features

| Starter roll scraper | Optional |

| Powered scraping auger | |

| Spirals on gate roll | |

| Pre-cutter/slicer |

Additional information

| Date collected | |

| Maintenance chains |