Key Features

- Integrated AutoTrac™ delivers faster cutting speeds while maintaining crop quality.

- Constant Header Speed allows you to set and maintain the best header speed for the crop and conditions, regardless of ground or engine speed.

- JDLink™ Connectivity is standard. Within your Operations Center account, activate the wireless service and your machine will stream machine and field data to your account.

Features

W200 Series cab

W200 Series cab

The W200 Series Self-Propelled Windrowers feature the largest cab in their class, designed to maximize operator comfort and machine productivity for long harvest days. The W200 Series’ four distinct cab options provide flexibility in matching the right features for every operation.

All configurations come standard with the following:

- JDLink™ system enabled

- AutoTrac™ assisted steering system ready

- 12 percent light-tinted rear window

- Automatic temperature control

- Business-band ready

- Interior rearview mirror

- Two halogen rear work lights

Choose from a variety of options the economy, standard, premium, and ultimate cab packages offer in terms of external lighting and mirrors, windshield wiper, sun shades, operator seat, upholstery, storage, refrigerator, radio, steering column, CommandARM™ controls, and display.

Economy cab

See below for image captions

See below for image captions

- Radio ready

- Six halogen front lights

- Single-blade windshield wiper

- Premium storage, upholstery, and styling

- Two manual, foldable, cab-mounted exterior mirrors (not pictured)

- Single-tilt steering column with telescoping controls (not pictured)

- 18-cm (7-in.) GreenStar™ 3 CommandCenter™ Display (non touch) (not pictured)

- Standard seat with air suspension, swivel, and fore-aft attenuation (not pictured)

Standard cab

See below for image captions

See below for image captions

Footrests

Footrests

- Standard AM/FM/WB/CD radio

- Eight halogen front lights

- Dual-blade windshield wiper

- Premium storage, upholstery, and styling

- Two powered, foldable, cab-mounted exterior mirrors (not pictured)

- Dual-tilt steering column with telescoping controls (not pictured)

- 18-cm (7-in.) GreenStar 3 CommandCenter Display (touch) (not pictured)

- Premium seat with lateral attenuation and a low-frequency suspension (not pictured)

- Footrests

Premium cab

See below for image captions

See below for image captions

Footrests

Footrests

- Premium AM/FM/WB/XM/Bluetooth® radio with subwoofer and armrest controls

- Four halogen and four light-emitting diode (LED) front lights

- Dual-blade windshield wiper

- Premium storage, upholstery, and styling

- Two powered, foldable, cab-mounted exterior mirrors (not pictured)

- Dual-tilt steering column with telescoping controls (not pictured)

- 18-cm (7-in.) GreenStar 3 CommandCenter Display (touch) (not pictured)

- Premium seat with lateral attenuation and a low-frequency suspension (not pictured)

- Front and rear sunshade

- Active refrigerator

- Footrests

Ultimate cab

See below for image captions

See below for image captions

Footrests

Footrests

- Premium AM/FM/WB/XM/Bluetooth radio with subwoofer and armrest controls

- Four halogen and four LED front lights

- Dual-blade windshield wiper

- Ultimate storage, upholstery, and styling

- Two powered, foldable, cab-mounted exterior mirrors (not pictured)

- Dual-tilt steering column with telescoping controls (not pictured)

- 26-cm (10-in.) GreenStar 3 2630 Display on the CommandARM (not pictured)

- Premium seat with lateral attenuation and a low frequency suspension (not pictured)

- Front and rear sunshade

- Active refrigerator

- Footrests

For a summary of all cab features, reference figure below:

Economy cab |

Standard cab |

Premium cab |

Ultimate cab |

|

Standard features |

||||

| JDLink enabled | X |

X |

X |

X |

AutoTrac-ready |

X |

X |

X |

X |

| 12 percent luminous transmittance (LT) tinted rear window | X |

X |

X |

X |

| Automatic temperature control | X |

X |

X |

X |

| Business-band ready | X |

X |

X |

X |

| Interior rearview mirror | X |

X |

X |

X |

| Two rear halogen work lights | X |

X |

X |

X |

Package options |

||||

| Entertainment | ||||

| Radio-ready | X |

|||

| Standard AM/FM/WB/CD radio | X |

|||

| Premium AM/FM/WB/XM/Bluetooth radio |

|

X |

X |

|

| Armrest display | ||||

| 18 cm-(7-in.) GreenStar 3 CommandCenter (non-touch) | X |

|||

| 18 cm-(7-in.) GreenStar 3 CommandCenter (touch) | X |

X |

||

| 26-cm (10-in.) GreenStar 3 2630 on CommandARM | X |

|||

| Seat | ||||

| Standard | X |

|||

| Premium | X |

X |

X |

|

| Steering column | ||||

| Single-tilt with telescoping controls | X |

|||

| Dual-tilt with telescoping controls | X |

X |

X |

|

| Footrests | ||||

| Operator footrests | X |

X |

X |

|

| Upholstery, storage, and styling | ||||

| Premium | X |

X |

X |

|

| Ultimate | X |

|||

| Exterior lighting | ||||

| Six halogen front lights | X |

|||

| Eight halogen front lights | X |

|||

| Four halogen and four LED front lights | X |

X |

||

| Exterior mirrors | ||||

| Two manual, foldable, cab-mounted mirrors | X |

X |

||

| Two powered, foldable, cab-mounted mirrors | X |

X |

||

| Windshield wipers | ||||

| Single blade | X |

|||

| Dual blade |

|

X |

X |

X |

| Sunshades | ||||

| Front sunshade | X |

X |

||

| Rear sunshade |

|

X |

X |

|

| Refrigerator | ||||

| Active refrigerator | X |

X |

||

Bluetooth is a trademark of Bluetooth SIG, Incorporated.

Forward visibility

Forward visibility

Forward visibility

Forward visibility is unequaled with the W200 Series Windrower cab. A large, wide-angle front windshield and cab-centered operator seat provide an unobstructed panoramic perspective from side-to-side and top-to-bottom. Operators can quickly scan the work area without having to look around cab obstructions.

The cab position relative to previous 450 models has been raised slightly and moved forward, providing better visibility of the platform and cutterbar.

Side-to-side visibility

Clear view of platform

Clear view of platform

Custom-shaped left- and right-windows and narrow cab cornerposts provide nearly 180 degrees of visibility scan in order to monitor all sizes of headers in the field and on the road.

The redesigned cornerpost display, swiveling CommandARM™ controls with display, and the ability to flip up the third display allow increased visibility during road transport.

Tinted rear window

Standard on all cab options, the 12-percent luminous transmittance (LT) tinted rear window reduces glare and reflection on cab controls, displays, and adjacent windows and helps to regulate cab temperature.

CommandARM

CommandARM

CommandARM

The CommandARM provides the operator with unmatched control of the windrower and platform. Controls are designed and positioned to enhance operator ergonomics and are easy to locate and use. Operators will appreciate the common look and feel of these control consoles in the windrowers, which are similar to the design used in John Deere tractors and combines.

Adjustment of the CommandARM meets the needs of every operator; it adjusts at an angle, fore and aft, and up and down for precise operator comfort.

The CommandARM provides access to the most frequently-used windrower controls:

- Field/road speed range

- Throttle: low idle, variable idle, high idle

- Platform engage/disengage

- Float adjust

- Platform speed adjustments

- Windrow merger speed, raise, lower (if equipped)

- Road hazard engage/disengage

- GreenStar™ 3 CommandCenter Display navigation

- Display menu shortcut buttons

- Climate control switches

- Work light switches

- Beacon light switches

- Hazard light switch

- Remote audio and radio tuning switches

Multifunction control lever

The controls vital to the operation of the W200 Series Windrowers are conveniently located on the multifunction control lever.

The ergonomic multifunction control lever gives the operator fingertip control of the following functions:

Rotary traction unit |

Draper traction unit |

|

| A | Platform float suspension adjustment, windrow merger position control | Reel raise/lower for/aft adjustment |

| B | Platform presets | |

| Preset 1: Full platform raise | Preset 1: Platform height, reel, tilt raise position | |

| Preset 2: Platform lower, AutoTrac™ automatic guidance engage | Preset 2: Platform advanced header control (AHC) resume, AutoTrac engage | |

| Preset 3: Toggle between two platform speed setpoints | Preset 3: Platform AHC resume | |

| C | AutoTrac resume (double tap to center track guidance line) | AutoTrac resume (double tap to center track guidance line) |

| D | Increase/decrease platform speed setpoint | Increase/decrease reel speed setpoint |

| E | Windrow merger enable/disable | Reel reverse |

| F | Platform raise/lower and tilt adjustment | Platform raise/lower and tilt adjustment |

Multifunction control lever

Multifunction control lever

The multifunction control lever is also associated with the following functions:

- Forward/reverse ground speed

- Automatically disengages the parking brake when moved from the park position with the engine running; the parking brake is automatically engaged when placed in park

- With platform enabled and on rotary traction units only, automatically raises platform when moved from forward to reverse position to prevent wrapping cut crop into conditioning rolls

GreenStar 3 CommandCenter Display

CommandCenter Display

CommandCenter Display

The GreenStar 3 CommandCenter Display is the central information system on all W200 Series Self-Propelled Windrowers. The GreenStar 3 CommandCenter Display provides:

- Header and diagnostic information vital to operation

- Adjustment of machine settings

- Infotainment access (if equipped)

- Interface to AMS applications and components

- Access to more machine diagnostic information enhancing serviceability

- Textual information on diagnostic trouble codes

- Interface to engine after-treatment system

Based on the choice of cab package, the W200 Series come with either an 18-cm (7-in.) display available in a touchscreen or non-touchscreen configuration or a 26-cm (10-in.) touchscreen display.

W200 Series Windrower PDU

W200 Series Windrower PDU

Traction unit information provided by the upper region (as seen in above image):

- (A) Stop, alarm, and information indicators

- (B) Engine power meter

- (C) Engine coolant temp

- (D) Park indicator

- (E) Turn signals

- (F) Diesel exhaust fluid gauge

- (G) Fuel gauge

- (H) High beam indicator

- (I) Exhaust filter cleaning indicator

- (J) Engine rpm

- (K) Ground speed

Platform specific information provided in the lower region:

Rotary platform |

Draper platform |

|

| L | Platform speed | Platform speed |

| M | Float pressure | Reel speed |

| N | Selected preset | Selected preset |

| O | --- |

Platform height/preset height indicator |

| P | --- |

Auto reel speed active |

| Q | --- |

Auto reel position active |

| R | --- |

Auto height sensing active |

| S | --- |

Auto tilt resume active |

| T | --- |

Platform level indicator |

Primary display unit (PDU)

The PDU features state-of-the-art electronic instrumentation and blends well with the narrow, right-hand cab post, providing excellent visibility to the header. The PDU is divided into an upper and lower region. The upper region provides traction unit information and the lower region provides platform specific information.

Radiator screen assembly

Radiator screen assembly

The W200 Series features several improvements over previous designs to keep the engine operating at optimal levels and improving engine life. Design features include:

- Increased screen area of 19 percent provides more air flow through the cooling package than previous models.

- Smooth, rounded path inside the wand and ducts keeps debris from slowing and plugging.

- Air lab engineered and field-tested ducting sized for air velocity and continual removal of debris.

- Wand backer plate helps stop debris from being sucked against the screen from the cooling fan for better cleaning performance.

- Cool air intake draws air from above chassis minimizing debris intake to cooling package.

- Stamped metal rear screen provides easier cleaning.

- Air-conditioner condenser and oil cooler assembly swing out for easy serviceability and cleaning

Oil cooler and air-conditioner assembly

Oil cooler and air-conditioner assembly

The W200 Series are tested in tough conditions of over 100°F to ensure the drives stay properly cooled for maximum life and reliability. The 94.6-L (25-gal) oil reservoir supplies oil to the pumps. Oil is cooled as it passes through the combination oil cooler and air-conditioner condenser assembly at the rear of the machine.

Live monitoring of the hydraulic oil temp at the left- and right-drive motors and reservoir limit switch protects against overheating during drive motor stall or high-grade terrain conditions.

Variable speed fan drive

Variable speed fan drive

The newly designed, eight-blade cooling fan incorporates a viscous drive system providing precise control over fan speed during operation. Optimization of the viscous fan speed leads to significant reductions in parasitic losses in certain operating conditions.

The fan speed is controlled by various factors such as engine coolant temperature, intake manifold air temperature, or hydraulic oil temperature. This level of control allows the fan to operate only at the required speed to keep the engine and cooling package at optimal operating temperature and thus reducing engine noise levels.

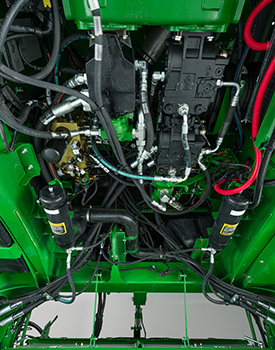

Heavy-duty drive pumps

Heavy-duty drive pumps

Heavy-duty drive pumps

The W200 Series Self-Propelled Windrowers feature heavy-duty Sauer-Danfoss® drive pumps, providing flow to larger, heavy-duty, bent axis wheel drive motors for increased power and higher ground speeds in the field and transport operating range. The pumps and wheel motor housings are made of heavy-duty cast iron for quiet and reliable operation.

Increased engine horsepower, heavy-duty drive pumps, and wheel motors create:

- More available ground torque for better management of hilly terrain

- Easier loading of the windrower onto the trailer for transport

- Provides increased reliability of the hydrostatic components

Servo-controls used on the hydrostatic pumps:

- Provide excellent control with minimal operator effort for steering or speed control

- Hydrostatic drive control lever maintains desired position when operating on hilly terrain

- Simplifies linkages for added reliability

- Reduces noise and vibration in the cab

Distribution gearcase

Distribution gearcase

The distribution gearcase drives the rotary platform pump and wheel motor pumps. The distribution gearcase is mounted directly to the engine and has a separate oil cooler for cooling.

Heavy-duty final drives

Dual-speed wheel motor

Dual-speed wheel motor

Planetary final drive

Planetary final drive

The windrowers use of large, heavy-duty planetary final drives powered by larger displacement motors provide increased torque rating for dependable operation in borders, irrigation wheel tracks, and rough field conditions.

With a final drive gear ratio of 36.8-to-1, the W200 Series Self-Propelled Windrowers have plenty of pulling power for climbing hillsides, loading on trailers, or operating in adverse field conditions.

Planetary final drives can be easily disengaged for towing.

Sauer-Danfoss is a trademark of Danfoss Power Solutions Inc.

Fuel and diesel exhaust fluid fill stations

Fuel and diesel exhaust fluid fill stations

The diesel fuel and diesel exhaust fluid (DEF) fill locations on the W200 Series Self-Propelled Windrowers provide convenient filling from ground level.

DEF sight gauge

DEF sight gauge

The DEF fill gauge keeps operators from over filling the tank, preventing spills and damage from freezing and expansion in cold weather.

Remote battery terminal

Remote battery terminal

A remote battery terminal, conveniently located on the left-hand platform near the fluid fill, provides power for the 12-V fuel pumps on refueling tanks.

Constant header speed

Constant header speed

A feature unique to the W200 Series Rotary Traction Units, constant header speed, is made possible by a state-of-the-art platform hydraulic pump control system that monitors platform speed and controls the pump to maintain a required speed. Constant header speed translates to a consistent cut quality and uniform windrow formation throughout varying crop conditions and terrain changes.

As crop conditions change, causing the head to slow, or if the engine begins to load as terrain changes, the control system diverts more oil flow to the platform drive motor to maintain the header speed set point. This widens the peak power range of the header, delivering the optimal power when it is needed most.

Other advantages of constant header speed include:

- Ability to run header at slower speeds in lighter crops, translating to less overall fuel consumption

- Ability to run engine speed under rated rpm and maintain set header speed

- Improved ramp up and down speeds upon starting and stopping platform, increasing life of header and platform drivetrain components

The industry-exclusive, rear-wheel steer assist system provides added control to the windrowers, enabling higher cutting and transport speeds.

IntelliAxle steer assist also has independent rear suspension, smoothing out the roughest field and road conditions and decreasing operator fatigue during long days in the field.

Independent rear suspension

Independent rear suspension

Independent rear suspension

The independent rear suspension contributes to a better quality of ride and less fatigue for the operator. The torsion axle design absorbs the shock experienced in rough terrains, allowing faster cutting speeds.

See rear suspension in action.

Rear-wheel steer assist

Rear-wheel steer assist

Rear-wheel steer assist

The rear-wheel steer assist system allows easier, more positive handling in the field as well as on the road during transport. Improved from the 450 Series design, the W200 Series features an electrohydraulic, proportionally-controlled rear steering system that provides tighter steering and better control at higher speeds.

In-field working speeds up to 25.7 km/h (16 mph) and road speeds up to 33.8 km/h (21 mph) are achieved with the help of this improved axle design.

Smooth, fluent steering helps the operator to maintain complete control of the windrower during sharp turns and aggressive field conditions. The steering sensitivity can be manually tuned by the operator using the CommandCenter™ display to match operator preference and field conditions.

The steer assist system provides three modes of steering aid as the machines travel through the speed ranges:

- Inactive

- At speeds less than 6.4 km/h (4 mph), the IntelliAxle steer assist system is not active and the front drive wheels solely control the machine steering.

- Field range

- At speeds above 6.4 km/h (4 mph), the IntelliAxle steering system begins to contribute to steering the machine by hydraulically assisting the turning of the rear caster wheels. The operator can set the desired sensitivity for the field range using the CommandCenter display.

- Transport range

- For transport range, the operator can set a different sensitivity independent from field range. If preferred, this gives the operator increased flexibility in tuning the steering system to desired sensitivity for higher transport speeds.

Faster field and transport speeds

Faster field and transport speeds are achieved with the increased controllability and stability provided by the rear-wheel steer assist system and independent rear-wheel suspension. The IntelliAxle system, when coupled with the W200 Series integrated AutoTrac™ guidance system, delivers unmatched performance and productivity.

W235 Windrower with 500R Platform

W235 Windrower with 500R Platform

W235 Windrower with 500D Platform

W235 Windrower with 500D Platform

The W200 Series Self-Propelled Windrowers exhibit the industry’s first fully-integrated AutoTrac steering system without the use of electrohydraulic pumps or universal type add-ons. The completely redesigned steering system features the industry’s only steering design, utilizing multiple steering systems to maximize controllability.

Operators will notice the increased accuracy and controllability of integrated AutoTrac compared to the previous AutoTrac Universal system on the R450 and 4995 Windrowers or older models. Additionally, this increased accuracy and controllability allows for faster operating speeds. Integrated AutoTrac on the W200 Series can run up to 27.4 km/h (17 mph) if conditions allow.

A unique hydraulic over mechanical design controls coarse adjustments of the drive pumps and an electrohydraulic proportional rear steering system executes fine adjustments, delivering the most accurate steering system in its class.

W200 Series Self-Propelled Windrowers are John Deere AutoTrac-ready from the factory requiring only a GreenStar™ 3 Display, AutoTrac activation, and StarFire™ receiver to enable. Click here to learn more about required components for AutoTrac on W200 Windrowers.

AutoTrac ensures more consistency and that more of the platform is engaging crop at all times, leading to increased productivity. This adds value to the operation by providing more consistent windrows, longer operating hours, and less fatigue.

Integrated AutoTrac on the W200 Series far outperforms previous windrower options, delivering faster cutting speeds and more acres cut in less time.

Uneven cutting surfaces such as irrigation berms and pivot wheel tracks make for challenging cutting. The W200 Series Windrowers feature independent platform float suspension to improve cut quality on non-level cutting surfaces and deliver improved performance.

Improved flotation on non-level surface

The independent float suspension delivers improved cut quality along irrigation berms and pivot tracks.

Adjusting the float suspension independently allows the platform to ride on the raised surface with proper flotation, reducing gouging and dirt buildup on the platform. Less dirt buildup means increased uptime and less dirt in the windrow, delivering higher quality hay and forage.

Quick, simple adjustment

Independent float adjustment

Independent float adjustment

Adjusting the float pressure can be done quickly and easily right from the multifunction control handle. Simply tap the left quad function to select the left, center (left and right simultaneously), or right float pressure adjustment. Increasing or decreasing float pressure can be done with the left quad or from the GreenStar™ 3 CommandCenter™ Display.

Quick, on-the-go adjustment translates to more time spent cutting and less time and stress on the operator to make adjustments to the float pressure.

John Deere value:

Performance |

Uptime |

Cost of operation |

|

|

|

Key Specs

| Engine - Model | 6.8L PSS Final Tier 4 |

| Horsepower | At 2,400 rpm: 193.9 kW 260 hp |

| Ground drive - Type | Two-speed hydrostatic |

| Fuel - Capacity | 568 L 150 U.S. gal. DEF: 26.5 L 7 U.S. gal. |

| Low range | 24.1 km/h 15 mph |

| High range 2 speed / Mid range 3 speed | 33.8 km/h 21 mph |

| Vehicle | Large drive tires and suspended rear axle in base |

| Seat | Air suspension, swivel fore-aft attenuation |

| Under frame clearance | 1,120 mm 44 in. |

| Weight - Total | 7348 kg 16,200 lb |

Engine

| Make | |

| Model | 6.8L PSS Final Tier 4 |

| Horsepower | At 2,400 rpm: 193.9 kW 260 hp |

| No. of cylinders | Six |

| Exhaust direction | Vertical |

| Engine displacement | 414 cu in. 6.8 L |

| Engine speeds | Low idle 900 rpm Variable idle Electronic adjustable from 1,700 to 2,450 rpm High idle (no load) 2,450 rpm Rated speed 2,400 rpm |

| Oil crankcase capacity (with filter) | 31.4 L 33.2 U.S. qt |

| Cooling system | 49.2 L 52 U.S. qt |

| Bearings |

Ground drive

| Type | Two-speed hydrostatic |

Hydraulic platform drive

| Number of pumps (Rotary/Auger) | One |

| Number of motors (Rotary/Auger) | One |

| Pump displacement | 89 cm3 5.43 cu in. |

| Motor displacemen | Per revolution: 75.4 cm3 Per revolution: 4.6 cu in. |

Platform float system

| Type | Hydraulic piston accumulator |

Final drives

| Type | Planetary double reduction heavy duty |

| Ratio | 36.8:1 |

Brakes

| Type / Activation | Parking brake automatically engages and disengages; integrated into multifuncton control lever |

Hydraulics

| Reservoir capacity | 94.5 L 25 U.S. gal. |

Fuel

| Capacity | 568 L 150 U.S. gal. DEF: 26.5 L DEF: 7 U.S. gal. |

Electrical system

| Alternator | 240 amp |

| Battery | Heavy-duty 12 V |

Tires

| Drive wheel standard | 520/80R38 radial bar |

| Drive wheel option | Bias button, 480/80R38 149A8 R1 radial bar (required on 994-4m platform) |

| Caster wheels | 14Lx16.1 8-ply ribbed |

| Caster wheels option |

Speeds

| Low range | 24.1 km/h 15 mph |

| High range 2 speed / Mid range 3 speed | 33.8 km/h 21 mph |

| High range with 3 speed |

Suspension

| Vehicle | Large drive tires and suspended rear axle in base |

| Cab | Large drive tires for smooth ride |

Cab

| Construction | Uni-body, welded |

| Glass | 7.08 m2 76.2 sq ft |

| Seat | Air suspension, swivel fore-aft attenuation |

| Steering column | Telescoping |

| Instructional seat | Standard |

| Windshield wiper | Single-blade or dual-blade |

| Air conditioner | Refrigerant R134a Capacity 2.7 kg 6 lb Filters Dry type, reusable Compressor Rotary Overload protection Low-pressure and high-pressure cutoff Standard with automatic temperature control |

Lights

| Front | Standard: six or eight halogen Optional: four halogen, four HID |

| Side | Four optional |

| Back | Two halogen standard |

| HID | Optional four front |

Display and input

| Type | Electronic touch and no touch option |

Dimensions (with platform installed)

| Overall length without platform | 5,900 mm 225.5 in. |

| Overall height | 3,760 mm 148 in. |

| Under frame clearance | 1,120 mm 44 in. |

| Wheelbase | 3,400 mm 142 in. |

| Tread width | 3,710 mm 146 in. |

| Turning radius |

Weight

| Without platform, full fuel | |

| Front axle | 4732 kg 10,432 lb |

| Rear axle | 2616 kg 5768 lb |

| Total | 7348 kg 16,200 lb |

Warranty

| Manufacturer's warranty | Full machine: 1 year Engine: 2 year; 2,000 hours |

Additional information

| Date collected |

Accessories and Attachments

Miscellaneous

John Deere DEF is compatible with all engines using selective catalytic reduction (SCR) after-treatment technology. This includes John Deere engines and equipment, off-road, and stationary equipment, on-road trucks, and automobiles. John Deere DEF may also be used in marine applications specifying 32.5 percent urea concentration.

John Deere DEF is a high-purity liquid injected into the exhaust system of SCR engines. John Deere DEF provides the essential chemical component required by SCR systems to remove nitrogen oxides (NOx) from diesel engine exhaust. It is recommended for all low-emission engines using SCR technologies, including heavy-duty off-road applications, as well as lighter-duty applications including, on-road vehicles and automobiles. Maintaining the purity of DEF is important to avoid malfunctions in the SCR system.

John Deere DEF is certified by the American Petroleum Institute (API) for diesel exhaust fluid and is manufactured to specifications defined by John Deere and ISO 22241.

Quality product is imperative to maintaining an effective SCR system and avoiding non-compliance or component failure. Follow these tips for best results:

- John Deere DEF is compatible with all engines using SCR after-treatment technology

- Always store in sealed containers and out of extreme temperatures

- When stored properly, expect a shelf life comparable to oils and coolants

- Purchase in amounts that can be used in a reasonable amount of time

- Only use approved compatible equipment when handling DEF

- DEF is crystal clear with a light ammonia smell. It should not be used if cloudy, has a colored tint, or a profound ammonia smell

- Never add DEF to the diesel tank

- The machine fill cap is blue with a DEF symbol

Features/benefits

- Convenient container sizes

- Translucent containers to monitor fluid levels

- Dispense nozzle include with each jug

- Drums are outfitted with 50.8-mm (2-in.) bung opening for direct pump insertion or closed-system dispensing valve and drop-tube installation

- Totes include integrated closed-system dispensing valve and drop tube

- Two popular tote sizes to match an operation

- 1041 l (275 gal.)…………. at 1,193 kg (2,630 lb)

- 1249 l (330 gal.)…………. at 1,429 kg (3,150 lb)

- Forklift tubes beneath tote cage for ease in handling

- ISO 22241 compliant for DEF handling procedures

- API certified

John Deere DEF is compatible with all engines using selective catalytic reduction (SCR) after-treatment technology. This includes John Deere engines and equipment, off-road, and stationary equipment, on-road trucks, and automobiles. John Deere DEF may also be used in marine applications specifying 32.5 percent urea concentration.

John Deere DEF is a high-purity liquid injected into the exhaust system of SCR engines. John Deere DEF provides the essential chemical component required by SCR systems to remove nitrogen oxides (NOx) from diesel engine exhaust. It is recommended for all low-emission engines using SCR technologies, including heavy-duty off-road applications, as well as lighter-duty applications including, on-road vehicles and automobiles. Maintaining the purity of DEF is important to avoid malfunctions in the SCR system.

John Deere DEF is certified by the American Petroleum Institute (API) for diesel exhaust fluid and is manufactured to specifications defined by John Deere and ISO 22241.

Quality product is imperative to maintaining an effective SCR system and avoiding non-compliance or component failure. Follow these tips for best results:

- John Deere DEF is compatible with all engines using SCR after-treatment technology

- Always store in sealed containers and out of extreme temperatures

- When stored properly, expect a shelf life comparable to oils and coolants

- Purchase in amounts that can be used in a reasonable amount of time

- Only use approved compatible equipment when handling DEF

- DEF is crystal clear with a light ammonia smell. It should not be used if cloudy, has a colored tint, or a profound ammonia smell

- Never add DEF to the diesel tank

- The machine fill cap is blue with a DEF symbol

Features/benefits

- Convenient container sizes

- Translucent containers to monitor fluid levels

- Dispense nozzle include with each jug

- Drums are outfitted with 50.8-mm (2-in.) bung opening for direct pump insertion or closed-system dispensing valve and drop-tube installation

- Totes include integrated closed-system dispensing valve and drop tube

- Two popular tote sizes to match an operation

- 1041 l (275 gal.)…………. at 1,193 kg (2,630 lb)

- 1249 l (330 gal.)…………. at 1,429 kg (3,150 lb)

- Forklift tubes beneath tote cage for ease in handling

- ISO 22241 compliant for DEF handling procedures

- API certified

John Deere DEF is compatible with all engines using selective catalytic reduction (SCR) after-treatment technology. This includes John Deere engines and equipment, off-road, and stationary equipment, on-road trucks, and automobiles. John Deere DEF may also be used in marine applications specifying 32.5 percent urea concentration.

John Deere DEF is a high-purity liquid injected into the exhaust system of SCR engines. John Deere DEF provides the essential chemical component required by SCR systems to remove nitrogen oxides (NOx) from diesel engine exhaust. It is recommended for all low-emission engines using SCR technologies, including heavy-duty off-road applications, as well as lighter-duty applications including, on-road vehicles and automobiles. Maintaining the purity of DEF is important to avoid malfunctions in the SCR system.

John Deere DEF is certified by the American Petroleum Institute (API) for diesel exhaust fluid and is manufactured to specifications defined by John Deere and ISO 22241.

Quality product is imperative to maintaining an effective SCR system and avoiding non-compliance or component failure. Follow these tips for best results:

- John Deere DEF is compatible with all engines using SCR after-treatment technology

- Always store in sealed containers and out of extreme temperatures

- When stored properly, expect a shelf life comparable to oils and coolants

- Purchase in amounts that can be used in a reasonable amount of time

- Only use approved compatible equipment when handling DEF

- DEF is crystal clear with a light ammonia smell. It should not be used if cloudy, has a colored tint, or a profound ammonia smell

- Never add DEF to the diesel tank

- The machine fill cap is blue with a DEF symbol

Features/benefits

- Convenient container sizes

- Translucent containers to monitor fluid levels

- Dispense nozzle include with each jug

- Drums are outfitted with 50.8-mm (2-in.) bung opening for direct pump insertion or closed-system dispensing valve and drop-tube installation

- Totes include integrated closed-system dispensing valve and drop tube

- Two popular tote sizes to match an operation

- 1041 l (275 gal.)…………. at 1,193 kg (2,630 lb)

- 1249 l (330 gal.)…………. at 1,429 kg (3,150 lb)

- Forklift tubes beneath tote cage for ease in handling

- ISO 22241 compliant for DEF handling procedures

- API certified

John Deere DEF is compatible with all engines using selective catalytic reduction (SCR) after-treatment technology. This includes John Deere engines and equipment, off-road, and stationary equipment, on-road trucks, and automobiles. John Deere DEF may also be used in marine applications specifying 32.5 percent urea concentration.

John Deere DEF is a high-purity liquid injected into the exhaust system of SCR engines. John Deere DEF provides the essential chemical component required by SCR systems to remove nitrogen oxides (NOx) from diesel engine exhaust. It is recommended for all low-emission engines using SCR technologies, including heavy-duty off-road applications, as well as lighter-duty applications including, on-road vehicles and automobiles. Maintaining the purity of DEF is important to avoid malfunctions in the SCR system.

John Deere DEF is certified by the American Petroleum Institute (API) for diesel exhaust fluid and is manufactured to specifications defined by John Deere and ISO 22241.

Quality product is imperative to maintaining an effective SCR system and avoiding non-compliance or component failure. Follow these tips for best results:

- John Deere DEF is compatible with all engines using SCR after-treatment technology

- Always store in sealed containers and out of extreme temperatures

- When stored properly, expect a shelf life comparable to oils and coolants

- Purchase in amounts that can be used in a reasonable amount of time

- Only use approved compatible equipment when handling DEF

- DEF is crystal clear with a light ammonia smell. It should not be used if cloudy, has a colored tint, or a profound ammonia smell

- Never add DEF to the diesel tank

- The machine fill cap is blue with a DEF symbol

Features/benefits

- Convenient container sizes

- Translucent containers to monitor fluid levels

- Dispense nozzle include with each jug

- Drums are outfitted with 50.8-mm (2-in.) bung opening for direct pump insertion or closed-system dispensing valve and drop-tube installation

- Totes include integrated closed-system dispensing valve and drop tube

- Two popular tote sizes to match an operation

- 1041 l (275 gal.)…………. at 1,193 kg (2,630 lb)

- 1249 l (330 gal.)…………. at 1,429 kg (3,150 lb)

- Forklift tubes beneath tote cage for ease in handling

- ISO 22241 compliant for DEF handling procedures

- API certified

- Auxiliary side lighting kit - 4031EBE32485

- Fire Extinguisher Mounting Bracket - 4031EAH170596

Two fire extinguishers and accommodating brackets are available through Parts.

The AT184159 dry chemical-type fire extinguisher and TY15630 bracket are recommended to be mounted using the two weld-nuts that are standard with the machine. These weld-nuts are located on the left-hand side of the hood by the operator's landing. Hardware is not included.

The TY25183 2.5-gal. water fire extinguisher and TY15183 bracket are recommended to be mounted on Z49348 lower landing panel. Hardware is not included.

- Flexible 4th step - 4031EBE32493

John Deere now offers optional 16.5Lx16.1 8 PR ribbed tires for A400, D450, R450, W235, and W260 Windrowers. The larger tires provide improved ride quality and flotation especially over irrigation pivot tracks and in muddy conditions.

BE32554 - Wheel kit

For A400, D450, R450, W235, and W260 Windrowers, the BE32554 kit will include two complete wheel assemblies with tires. BE32554 is not compatible with 316M mergers due to frame clearance issues.