Key Features

- Accurate seed metering capability

- Wide variety of working widths and row spacings

- Ground drive system with dual-range sprocket

- Durable mainframe and wings

Features

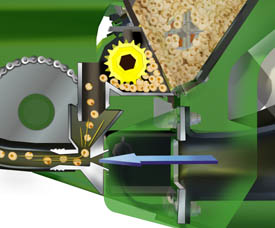

Seed meter and venturi

Seed meter and venturi

Metering of the seed is done at the tanks. While metering in volume, the co-efficient of variation from opener to opener is just 2 percent at the feed wheel. The population rates are controlled by meter speed as opposed to varying the amount of meter flute exposure as on a box drill.

By using this method, population rates can be better controlled, resulting in lower amounts of population variance from meter to meter. That is better than any other volumetric metering system on the market today.

The 1990 Central Commodity System (CCS™) also features metering gates at each individual metering wheel. This allows the operator to set the seed gate based on the seed size and population rate, to allow for even greater control of the population rates. The meter gate can also be used to shut off seed flow to an individual seed meter if desired.

Meter rollers

Meter rollers

The 1990 CCS features three optional meter rollers:

-

The narrow black roller is recommended for low application rate crops such as sorghum.

-

The medium-rate black roller is used for application rates of up to 89.7 kg/ha (80 lb/acre).

-

The white high-rate roller is used for larger seeds and for high application rates. The white high-rate roller is also used for crops such as barley, oats and rice on 1990 CCS dual-rank models.

The metering rolls are interchangeable as well. Available metering bundles allow the operator to change over the complete meter assembly when changing crops from a high-rate crop to a lower population rate crop.

Oscillating agitation

Oscillating agitation

The 1990 CCS features an oscillating seed agitation system. The oscillating-style agitation system is more aggressive than a rotating style to be able to handle crops prone to bridging such as barley and rice.

Meters are color coded for quick reference:

Meter rollers |

|

| Black narrow | Low rates and small seeds (sorghum/milo only) |

| Black medium | Medium rates to 80 lb/acre; medium and small size seeds (milo and wheat only) |

| White | High rates of wheat, barley, oats, rice, and large seeds (soybeans) |

They can be easily removed or interchanged when changing over from seeding one crop to another.

Meter rolls are available from 18 port to 34 ports or nine rolls to 17 rolls per meter section.

Meter rollers are compatible with a wide variety of crops and rates.

IMPORTANT: 1990 CCS single-rank machines are compatible with soybeans, wheat, and milo. 1990 CCS dual-rank machines are compatible with soybeans, wheat, milo, barley, oats, and rice.

1990 Central Commodity System (CCS™) control box

1990 Central Commodity System (CCS™) control box

Seed populations can be changed on the go with electronic population rate control (EPRC).

A simple adjustment (switch A) in the cab allows either increasing or decreasing the seeding rates to match the target population. The EPRC allows operators to keep tight controls on population rates by allowing in-cab adjustments of population rates. The available seed-counting system allows viewing actual soybean population rates on the go.

Half-width disconnect (switch B) is in base equipment to allow seeding point rows or headlands without overlapping, saving seed and input costs.

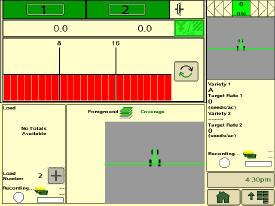

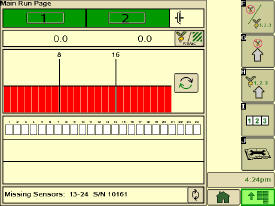

SeedStar™ 2 system with 1990 CCS in a run page

SeedStar™ 2 system with 1990 CCS in a run page

The half-width disconnects can also be activated and deactivated from within the SeedStar 2 main run page. The green boxes at the top of the screen with 1 and 2 in them indicate that both half widths of the drill are seeding.

Half-width disconnect clutch

Half-width disconnect clutch

The electrically operated half-width disconnect clutch allows the operator to shut off half of the drive system conveniently from the tractor cab.

Air system

Air system

1990 Central Commodity System (CCS™) air system features:

- Uses an air-delivery system to gently deliver the seed from the seed meters to the individual openers

- This air-delivery system provides accurate seed metering and increased productivity

- Also offers wide working widths in a compact transport package

NOTE: Tanks are not pressurized.

CCS fan

CCS fan

Plenum

Plenum

Airflow is generated by a 44.7-cm (17.6-in.) diameter, hydraulically powered fan.

The large-diameter fan and high-airflow:

- Gently move seed to the openers

- Minimize the chances of the air system plugging

- System requires up to 34.1 L/min (9 U.S. gpm) of hydraulic flow and a closed-center hydraulic system

- The fan is strategically located to minimize the chance of foreign material entering the air system

Air is then channeled to the plenums, which distribute the air evenly among all of the air runs.

Venturi

Venturi

After the air has left the plenum, it enters the venturi area.

- The venturi generates an area where the seed is delivered into the airstream after it has fallen from the metering wheel

- The dual-rank 1990 CCS features:

- Larger-sized hoses

- Larger venturi throat openings

- Benefit: provide the system the capability of higher rates and additional crop choices

Blockage flow sensor

Blockage flow sensor

It is important to have the ability to monitor seed flow out of each individual opener.

The SeedStar™ 2 blockage system allows the operator to monitor product flow to each individual opener.

A product flow sensor is mounted on each 1-in. seed hose located after the flow splitter. The optical flow sensor uses infrared technology for seed flow detection to ensure that the sensor does not impede product flow through the seed hose.

SeedStar 2 blockage

GreenStar™ display

GreenStar™ display

Blockage

Blockage

The SeedStar 2 display gives the operator an in-cab warning as to the exact row that has been blocked. The console will provide an audible alarm and display the exact row number to the operator that has become plugged. The SeedStar 2 display also has the ability to monitor seed population rates at the meters, reducing the number of in-cab consoles that are required by the producer.

SeedStar 2 works on both single- and dual-rank models. On dual-rank machines the sensor is located after the wye splitter. Single-rank machines have a sensor installed on each individual row.

Growers have historically had to make some difficult planting and seeding decisions due to weather. Operators have been forced to plant in wet conditions that are far from optimal in order to plant within the optimum planting window. Those operators have experienced poor performance from wet soils working in between the depth gauge wheel and the opener disk and not having a way out. This creates the possibility of the depth gauge wheel or opener disk to seize up and drag through the soil.

The spoke gauge wheel is a solution for operators who plant in these conditions to allow the mud and debris that get caught behind the depth gauge wheel to easily flow through the wheel and continue providing superior depth performance.

The spoke gauge wheel is designed for optimum performance. Its features include serviceable, stamped inner and outer rims. The wheel also has cast spokes and bearing hubs for increased strength. This allows smaller spokes, creating larger open surface area for mud and debris to flow more easily than competitor’s wheels. Another improvement over the closed gauge wheel is a snap-ring bearing retention. Simply remove the snap ring, replace the bearing, and place the snap ring back.

Gauge wheel

Gauge wheel

Gauge wheel

Gauge wheel

Heavy trash fields from no-till environments have also tested very well with the new spoke gauge wheel. Some growers provided feedback of crop residue getting inside and jamming up the gauge wheel and opener. This spoke gauge wheel has shown exceptional performance within these areas as well. These wheels are compatible with both 90 Series openers on seeding tools and planter row-units.

Below is a chart that demonstrates a competitive advantage over MudSmith™ wheels for mud and residue flow:

| MudSmith | John Deere | Percent improvement | |

| Open area | 329 cm2 (51 cu in.) | 471 cm2 (73 cu in.) | 43 percent |

| Rim height | 1.9 cm (3/4 in.) | 1.4 cm (9/16 in.) | 25 percent |

| Spoke width | 3.5 cm (1-3/8 in.) | 1.9 cm (3/4 in.) | 45 percent |

The wheel is serviceable along with other parts.

- AA86055 – complete wheel assembly

- A101570 – inner wheel rim half

- A101571 – outer wheel rim half

Not compatible in dual gauge wheel applications.

MudSmith is a trademark of MudSmith, LLC.

ProSeries Openers

ProSeries Openers

ProSeries Openers are in base equipment on all 1890 and 1895 Separate Fertilizer Placement (SFP), 1990 Central Commodity System (CCS™), and 1590 Air Drills.

On the 1890 models, the single-disk openers are on 190-mm (7.5-in.) or 254-mm (10-in.) row spacing. On 15.25-m (50-ft) and 18.3-m (60-ft) 1890s, the 190-mm/380-mm (7.5-in./15-in.) or 254-mm/508-mm (10-in./20-in.) dual-row spacing feature is in base equipment. The single-disk openers provide consistent and accurate seed placement.

The ProSeries Openers are gang mounted and are hydraulically raised and lowered. The hydraulic downforce system also offers a wide range of downforce settings for the openers.

Active hydraulic downforce pressure valve

Active hydraulic downforce pressure valve

The active hydraulics:

- Work in conjunction with the opener spring

- Provide an adjustable range of 75 kg (165 lb) to 180 kg (400 lb) of down pressure per opener

- Benefit: penetrate hard soils and heavy residue

- The cylinders allow the openers to travel up or down an additional 405 mm (16 in.) with active hydraulic down pressure to follow the ground

- Provide the openers additional pressure when needed or allow the openers to go into relief if the pressure becomes too high

The down pressure:

- Is easily adjusted with the pressure valve located on the front of the mainframe

- Provides the operator the ability to quickly adjust, or dial in, the down pressure as operating conditions change

NOTE: For additional ballast in hard-to-penetrate conditions, tractor suitcase weights may also be added to the mainframe and wings to obtain maximum down pressure per opener.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 200-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

Key Specs

| Working widths | |

| Spacing | |

| Number of ranks | |

| Openers | Style Single disc no-till Rank lock-up Front optional Diameter 45.72 cm 18 in. Down pressure 74.8 to 181.4-kg/opener 165 to 400-lb./opener |

Sizes

| Working widths | |

| Spacing | |

| Number of ranks | |

| Number of sections | 3 |

Dimensions

| Transport height | 3.63; 4.55; 4.45; 4.85 m 11-ft. 11-in.; 14-ft. 11-in.; 14-ft. 7-in.; 15-ft. 10-in. |

| Transport width | 4.37; 5.59 m 14-ft. 4-in.; 18-ft. 4-in. |

| Road clearance | 21.59 cm 8.5 in. |

| Overall length | 7.49 m 24-ft. 7-in. |

| Centerframe width | 3.48; 4.62 m 11-ft. 5-in.; 15-ft. 2-in. |

| Weight before ballast | 8,528; 10,115; 11,203; 11,657 (7.5-in. spacing); 7,575; 9,026; 9,934; 10,251 (10-in. spacing) kg 18,800; 22,300; 24,700; 25,700 (7.5-in. spacing); 16,700; 19,900; 21,900; 22,600 (10-in. spacing) lb |

| Available ballast | |

| Frame | Cross members 102 x 152 mm 4 x 6 in. End tubes 51 x 152 mm 2 x 6 in. Hitch 76 x 152 mm 3 x 6 in. |

| Clearance from rank to rank | 134.11 cm 52.8 in. |

| Centerline of mainframe wheel support tube to centerline of wing wheel support tubes | |

| From ground to platform | |

| From ground to top of lid | |

| From ground to top of lights | |

| From ground to top of safety rail | |

| Lateral frame clearance, opener to opener |

Tires

| Mainframe standard | (8) 11L-15, 12 PR |

| Mainframe bolt pattern | |

| Wings standard | (4) 11L-15, 8 PR |

| Wings bolt pattern | |

| Centerframe tires and wheels | |

| Wheel spacing, center frame | |

| Wing tires and wheels |

Openers

| Style | Single disc no-till |

| Rank lock-up | Front optional |

| Disk | Diameter 45.72 cm 18 in. Angle 7 degree (angle) |

| Down pressure | Style Active hydraulic downforce 10-in. space 74.8 to 204.1-kg/opener 165 to 450-lb./opener 74.8 to 181.4-kg/opener 165 to 400-lb./opener |

| Depth control | Description Depth gauging wheel Gauge wheel size 11.43 x 40.64 cm 4.5 x 16 in. Range 1.27 - 8.89 cm 0.5 - 3.5 in. Increments 0.64 cm 0.25 in. |

| In-Furrow press wheel | Material Semi-pneumatic rubber Packing force 2.3 - 20.4 kg 5 - 45 lb 2.54 x 25.40 cm 1 x 10 in. |

| Furrow closing | Description 15-degree closing wheel Size 2.54 x 30.48 cm 1 x 12 in. Material Cast iron Down force 11.8 - 19.5 kg 26-43 lb |

| Double-Shoot capable |

Additional information

| Date collected | |

| Fast start/Quick start | |

| Four-section seed on/off | |

| Implement harness connection, 12 VDC | |

| Implement harness connection, 56 VDC | |

| Operator interface | |

| Seed blockage sensor per row | |

| Tool-mounted alternator |

Equipment compatibility (at 1.5 in. seeding depth and 8 mph)

| Tractor drawbar power required, 10-in (25.4 cm) models | |

| Tractor drawbar power required, 15-in (38.1 cm) models | |

| Tractor drawbar power required, 7.5-in (19.1 cm) models |

Seed Metering

| Crops | |

| Description | |

| Max Volumetric Seeding Rates - Barley | |

| Max Volumetric Seeding Rates - Milo/Sorghum | |

| Max Volumetric Seeding Rates - Oats | |

| Max Volumetric Seeding Rates - Rice | |

| Max Volumetric Seeding Rates - Soybean | |

| Max Volumetric Seeding Rates - Wheat | |

| Metering Drive Type |

Seed Storage

| Blower | |

| Blower drive type | |

| Distribution hose size | |

| Seed Distribution | |

| Tank Description | |

| Tank Fill Screen | |

| Tank Scales | |

| Total Tank Capacity | |

| Type |

Tractor requirements

| Hydraulic Power Beyond | |

| Minimum electrical capacity | |

| Minimum hydraulic capacity | |

| Minimum number of SCV's |